The trend of CNC machining of precision instrument parts in the medical industry

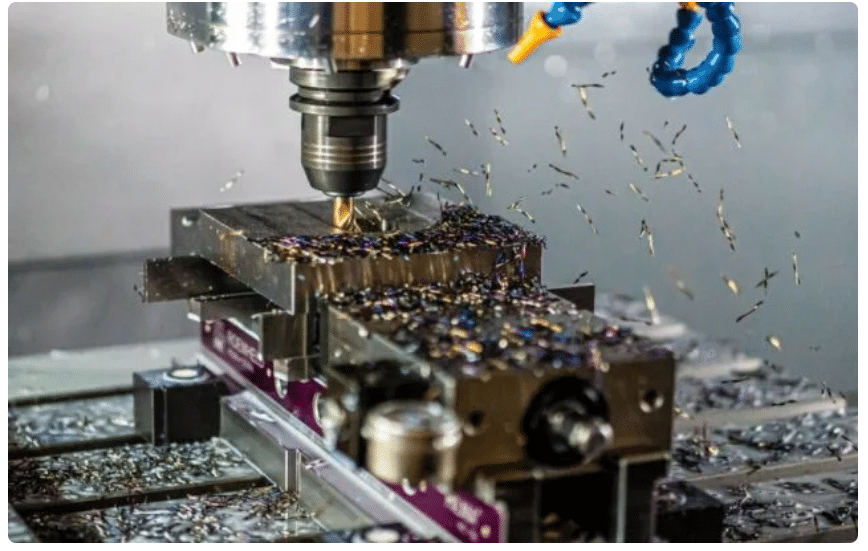

With the continuous progress of society and technological innovation, precision CNC machine tools are increasingly used in the medical field. Medical device parts have the characteristics of complex structure, tough materials and difficult processing. The CNC processing of medical precision instrument parts is directly used for finished products, so the requirements for appearance are very high, and it must be achieved with relatively professional processing technology.

1、 CNC machining challenges for precision instrument parts in the medical industry:

CNC machining technology of precision instrument parts is an advanced manufacturing technology developed to adapt to modern high-tech. In recent years, with the deepening of intelligent manufacturing in China, CNC processing technology for precision instrument parts has made greater contributions to the medical device industry. CNC machining of precision parts is a process widely used in the field of medical care, which is often used to manufacture implants, medical equipment and surgical tools, such as scalpels. Strict tolerance and fast turnover are particularly important for projects such as titanium hip implants.

2、 CNC machining trend of precision instrument parts in medical industry:

With the development of the medical device industry, there will be more and more types of medical devices, more and more complex structures, and higher accuracy requirements. In order to meet the requirements of multiple varieties and high precision of medical devices, high-speed, high-precision, intelligent, compound and environment-friendly precision machining has gradually become the main development direction of CNC machining of precision instrument parts of medical devices.

Supporting CNC processing of medical precision instrument parts

CNC machining of precision instrument parts has made great contributions to the progress of the medical industry and will continue to be an integral part of future progress. In particular, five axis NC machining is often used for stainless steel medical parts. Due to its good biocompatibility, good mechanical properties, excellent resistance to body fluid corrosion, and good processing formability, it has become a widely used medical implant material and medical tool material in clinical applications.