Various requirements for two-color injection molding

Material requirements

The matching materials for two-color injection molding must meet two basic compatibility conditions, namely, adhesion compatibility and processing compatibility.

technological requirements

Soft and hard glue dual radiation design

There must be a certain temperature difference between the melting points of the two materials, generally 60 ℃ is recommended, and at least 30 ℃ is recommended. The melting point temperature of the first shot material is high, generally the first shot is PC or PC/ABS, the second shot is TPU or TPE, the PC thickness is 0.6-0.7mm, and the software is above 0.4mm.

The contact area shall be widened as much as possible, and the bonding force shall be increased by making grooves, or the core pulling shall be used for the first shot, and the materials for the second shot shall be injected into the first shot. The surface of the first shot mold shall be rough as much as possible.

Transparent and non transparent bijection design

Dual reflection design of small lenses: the first lens is made non transparent, the second lens is made, the first lens uses PC with high melting point as far as possible, and the second lens uses PMMA.

Transparent and non transparent dual radiation design for decoration: the first radiation is non transparent material, and the second radiation is transparent material. PC with high material temperature is commonly used as non transparent material, and PMMA or PC is used as transparent material for the second radiation. PC needs to be protected by spraying UV. PMMA can choose UV or strengthening. If there are characters on the surface, UV must be selected.

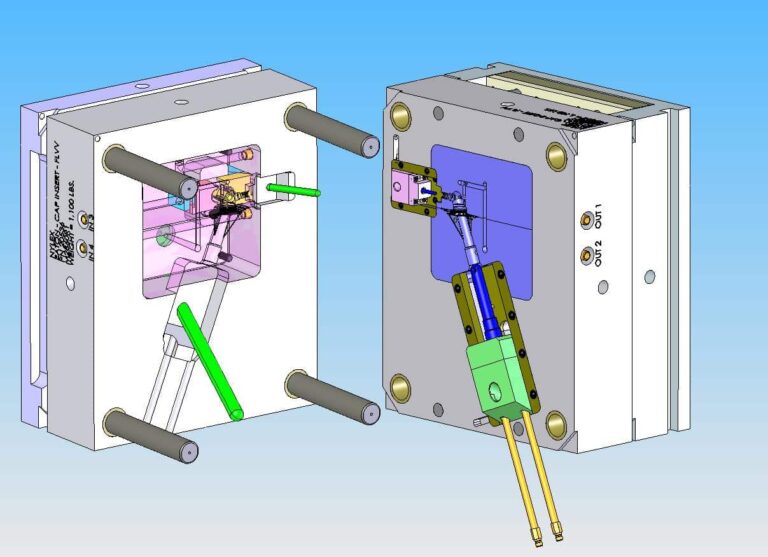

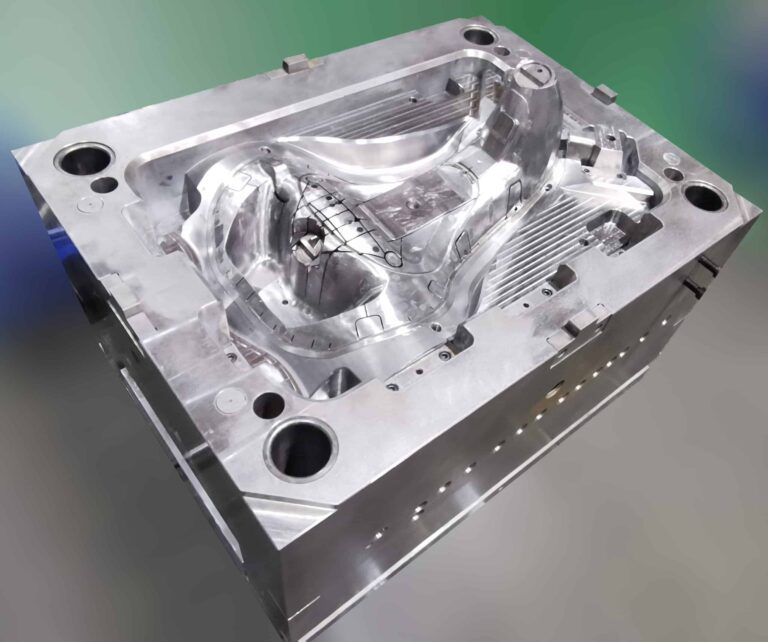

Die requirements

Two color mold: a mold in which two plastic materials are injected on the same injection molding machine in two times, but the product is only molded once. Generally, this molding process is also called double material injection molding, which is usually completed by a set of molds and requires a special two-color injection molding machine. Generally, there are the following requirements:

1. The two shapes of the master die must be different, forming a product separately, while the two shapes of the male die must be exactly the same;

2. The front and rear dies of the die must be aligned after rotating 180 ° in the center;

3. The total thickness of front formwork panel plus A plate shall not be less than 170mm. The maximum mold thickness, minimum mold thickness, KO hole distance, etc. shall be carefully checked;

4. The nozzle of the three plate mold should be designed to automatically demould;

5. When designing the master mold for the second injection molding, in order to avoid the second master mold scratching the rubber position of the first molded product, a part of void avoidance can be designed. However, the strength of each sealing position must be carefully considered (i.e., during injection molding, will the plastic deform under high injection pressure, leading to the possibility of batch front for the second injection molding?);

6. During injection molding, the product size of the first injection molding can be slightly larger, so that it can be pressed more tightly with another male mold during the second molding, so as to achieve the role of sealant;

7. Pay attention to whether the flow of plastic will impulse the first molded product to deform the rubber position during the second injection molding;

8. Before clamping plates A and B, pay attention to whether the front die slider or inclined jack will reset first and crush the product;

9. The water conveyance layout of the two master molds and the male mold shall be as adequate and balanced as possible;

10. 99% of the time, the hard rubber part of the product is injected first, and then the soft rubber part of the product is injected, because the soft rubber is easy to deform.