Engaged in injection molding industry for more than ten years, but also just know a little skin, a pair of molds from product development to 3D printing verification, from mold design, to processing and manufacturing, and then to injection molding production, assembly into finished products, which involves a very wide range of types, of course, now most companies are refined, generally each of us are engaged in a small area, but even if the division is fine enough, are enough for us to learn a lifetime of mold people After all, technology and equipment are being updated every moment, and we have to keep up with the pace at any time, or we will fall behind, or be eliminated, so we always say that technology is never ending.

Today I want to talk about the most basic of our injection molding is also the first step in the introduction of injection molding, that is, we must understand what is injection molding.

Injection molding is actually a simple and common understanding of various raw materials by high temperature melting, injection molding machine injection into a pair of processed mold molding, to get the desired product. If you have no contact, you may not know what the mold is? I make an analogy, as if we look at the adults as a child to make patties with the wooden tools, and make moon cakes and snacks and other tools, the production and processing of various shapes, patterns, text, etc., the things made and that is the same, called the mold, I think this should be better understood.

Of course injection molds according to the product there are simple, there are complex. There are small molds and large molds. Please follow me to understand how many parts of an injection mold.

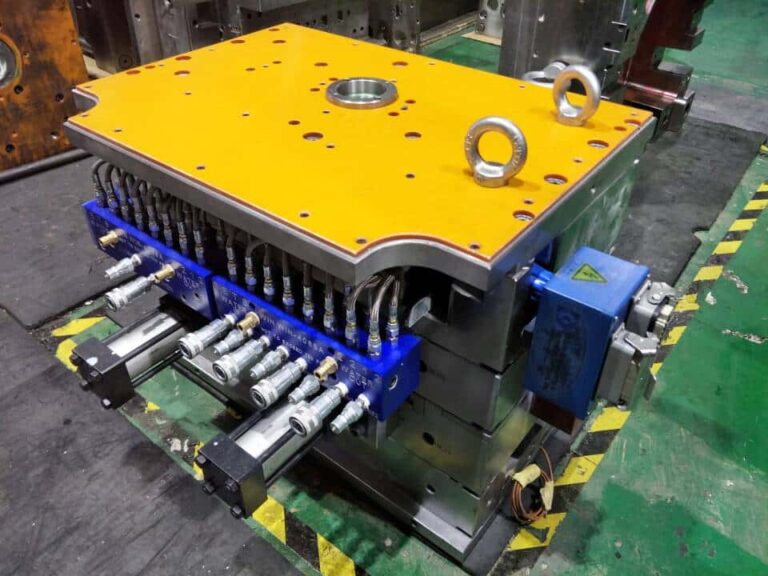

Mold frame

Nowadays, mold frames are standardized. The common ones are two-plate mold, three-plate mold, and various types of mold frames evolve according to the product structure, such as rear mold with push plate, rear mold with ejector plate, front mold with ejector plate, etc. However, no matter how they evolve, they are inseparable from the molding system, glue feeding system, cooling system, and ejector system.

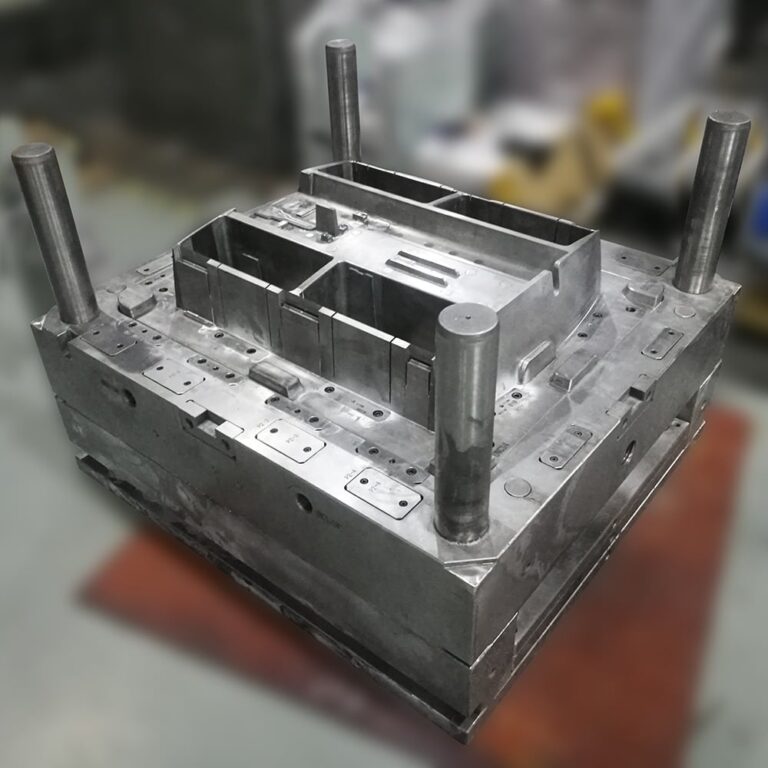

Molding system

Molding system is composed of front cavity and back cavity, some people call it male mold and female mold, our plastic products are what kind of mold, then the molding system is equivalent to a mirror of this product, through the processing equipment (computer gong, spark machine, grinding machine, wire cutting, milling machine) in the front cavity and back cavity processing out.

Glue feeding system

The pouring system is divided into common giblet feeding and hot runner feeding. The common giblet feeding is divided into direct feeding, big water mouth, point water mouth, diving mouth, bullhorn feeding, etc. The mold cost is low, but the injection molding cycle is long and the material consumption is large. Hot runner although the mold upfront cost is high, but high efficiency and material saving consumption less, like needle point type into the glue, are no glue saving consumption, if the beer goods more, will greatly reduce the cost, so if the product quantity is large, now are using hot runner.

Cooling system

Cooling system is used in injection molding to cool the mold, a pair of mold cooling system design is directly related to the mold size accuracy. Of course, the cooling here can not be one-sided understanding is to use cold water cooling, according to the need such as the product is light in front of the mold need to use oil to raise the mold temperature, the plastic liquidity of low mold need high temperature, to use the heat pipe to heat the mold.

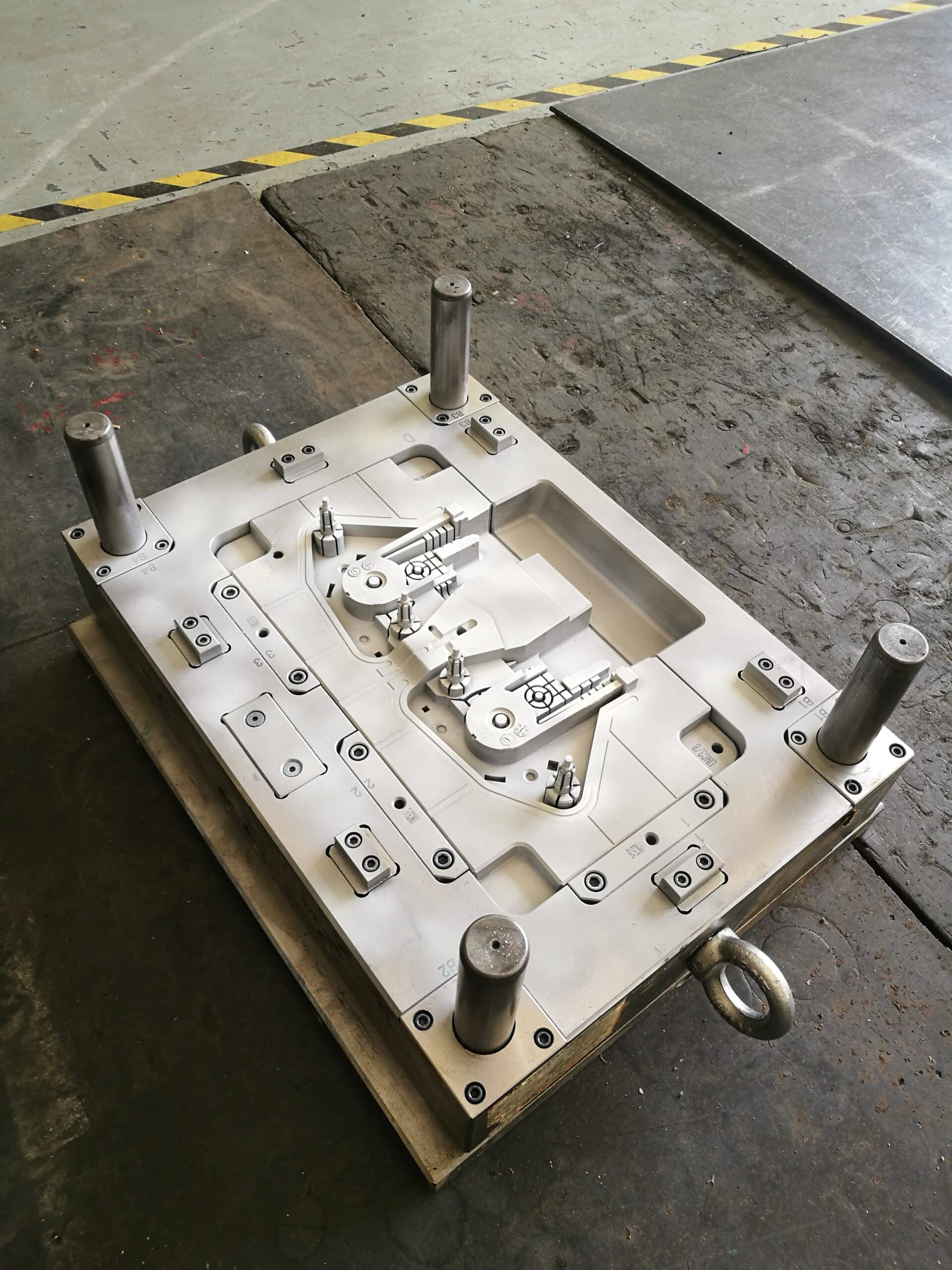

Ejector system

Ejector system is used ejector pin, push plate, air blow, grip teeth and all the methods that can make the product out of the mold. It also includes the release mechanism of complex products, such as the side holes of our products, inverted buckle and so on can not be smoothly released from the mold design of a variety of line position, oblique top. Such as line position with line position, line position with slant top, line position with ejector, etc., slant top such as large angle slant top, rising type slant top, etc.

The above is a small personal injection mold, there are many shortcomings, welcome to correct, thank you! I hope the above can help some friends in need, if you think you can, please spend 0.1s of time to point a love, or forward to friends in need.