What are the technical points of plastic crate injection moulds?

In addition to the daily use and maintenance of the crate mold life, another thing that determines the life of the mold is the mold steel and mold design.

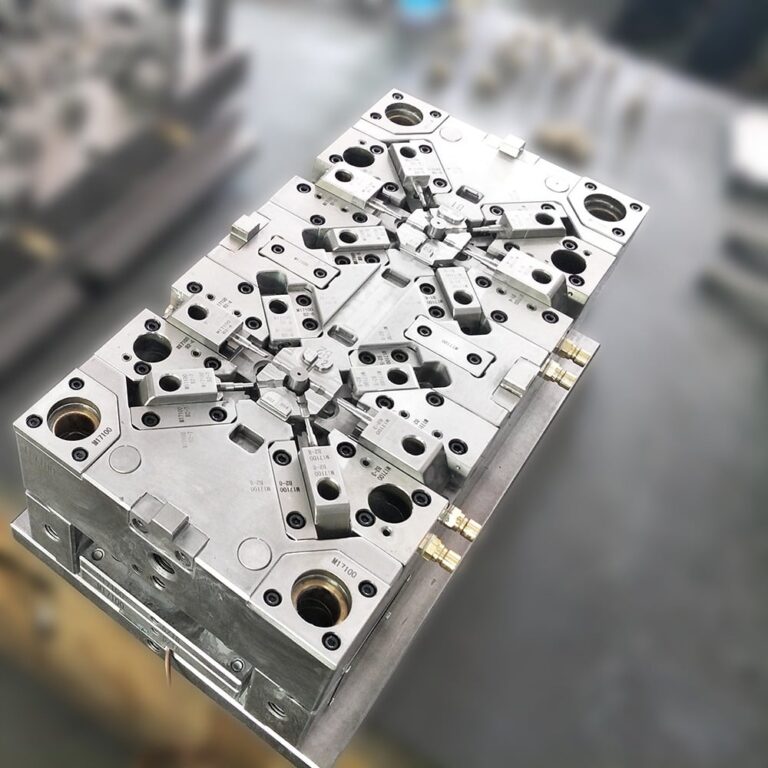

First of all, we should choose the right steel material for the mold frame and mold core cavity part. For example, to produce a pair of one out of one crate molds, you must use hard pre-hardened steel for the mold frame, and then choose the right mold standard parts. The mold kernel slider must be hardened.

Second, must grasp the hardness of each piece of steel material, not too hard, mold steel should be heat-treated (QC department hardness tester test)

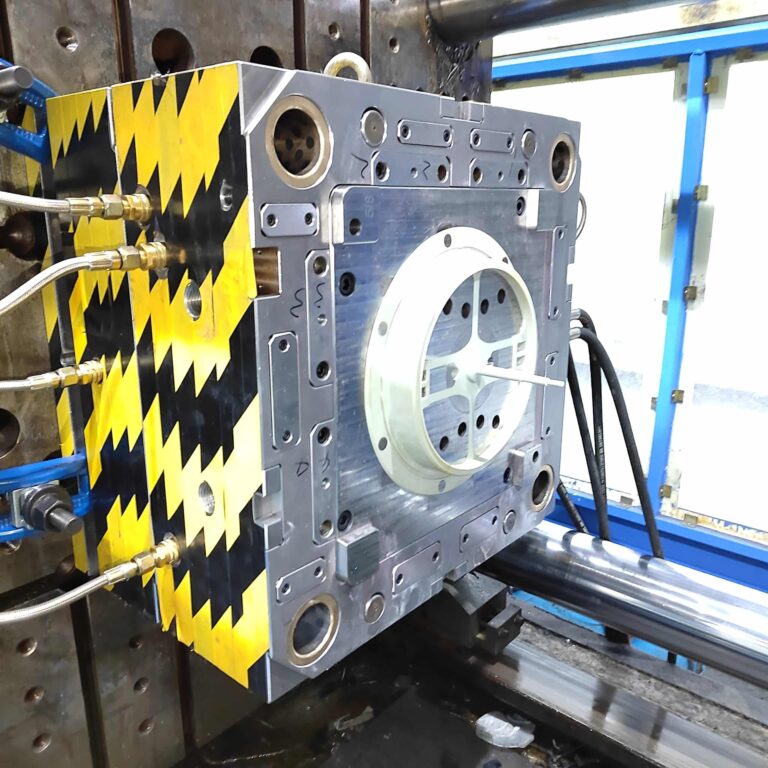

Then, the contact surface and guiding part of the crate mold must be finely processed, and the wear-resistant block must be made of P20 or above, and no manual work can be used.

Conclusion, some mold companies will be such as using back material for mold injection, then we must consider the following two points: A. How to ensure that the fine impurities in plastic do not damage the core and cavity; B. How to prevent impurities from entering the cavity. Plastic crate mold handle at the exhaust system: crate handle at the exhaust is a very important subject, because when the crate load load, the two ends of the handle is the key point of the load force. If the mold on the 2 handles at the exhaust is not good, it will leave a clear fusion seam, the product will be easily damaged from this point.