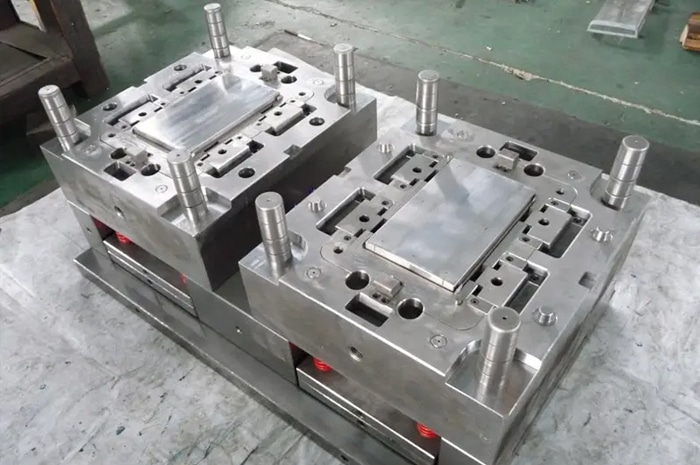

The selection of insert materials mainly includes four aspects:

1. Hardness;

2. Wear resistance;

3. Strength and toughness;

4. Corrosion resistance.

The selection of mold insert materials is mainly based on the batch of plastic products and the types of plastics. The products are ordinary plastics, such as ABS, PP, PC, etc. Pre hardened and tempered steel of P20 type is usually selected. If the batch of products is large, quenched and tempered steel of H13 type is selected.

High finish or transparent plastic products, such as PMMA, PS, AS and other plastics or plastics containing glass fiber, are mainly made of corrosion-resistant stainless steel of type 420.