What do I need to pay attention to during the manufacturing process of injection molds?

The reason why injection molds are the mother of industry is that they can produce various shapes of plastic products, simply put, they are like Play-Doh for children, which can be created into various shapes and appearances. However, injection molding is a delicate job. There are many details that need attention. Let’s take a look at what we need to pay attention to, right?

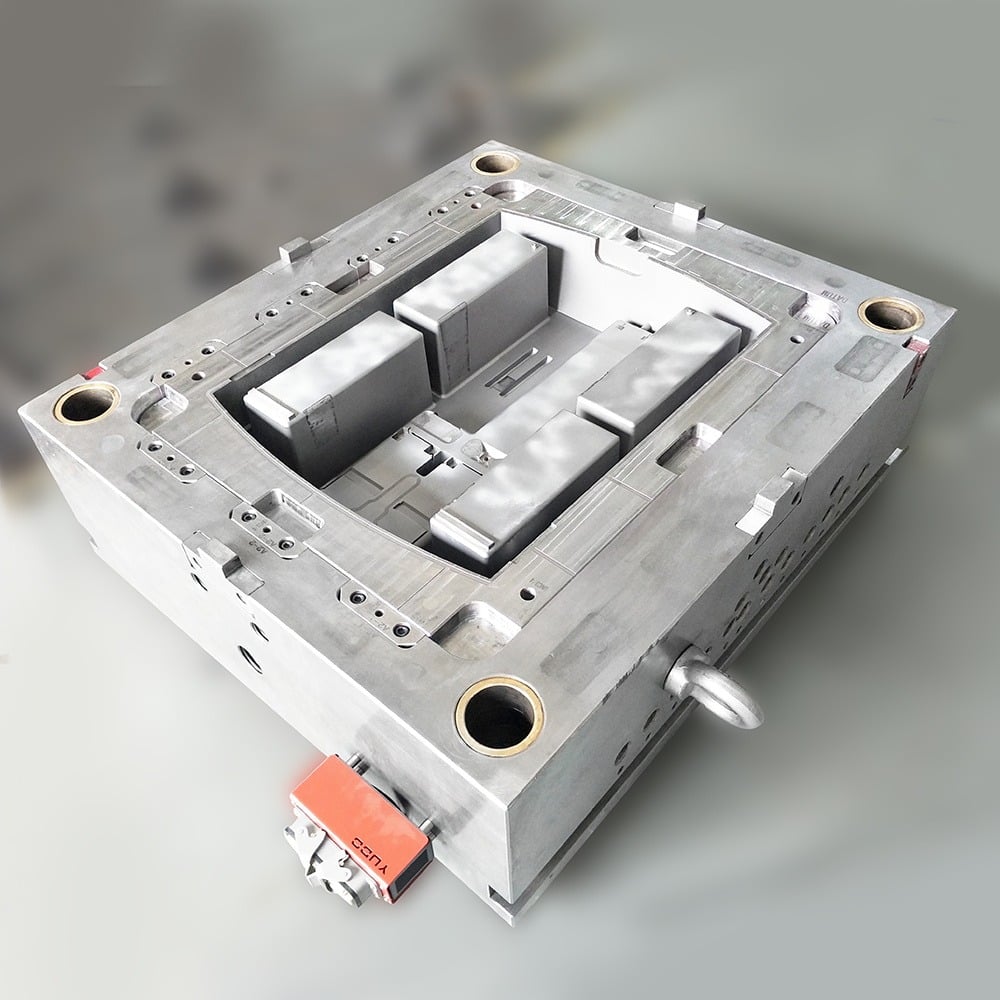

1) Avoid sharp corners

I believe that many people will ask why in the process of injection mold processing and manufacturing, to avoid the generation of sharp corners? In fact, it is not difficult to understand in order to smooth the surface of plastic products, it is necessary to ensure that the production of such plastic products used in the injection molding tool can not exist sharp corners, so as to make the production of plastic products look more round and smooth shape, but also to avoid the emergence of problems such as sticky mold, which is conducive to improving the quality of plastic products.

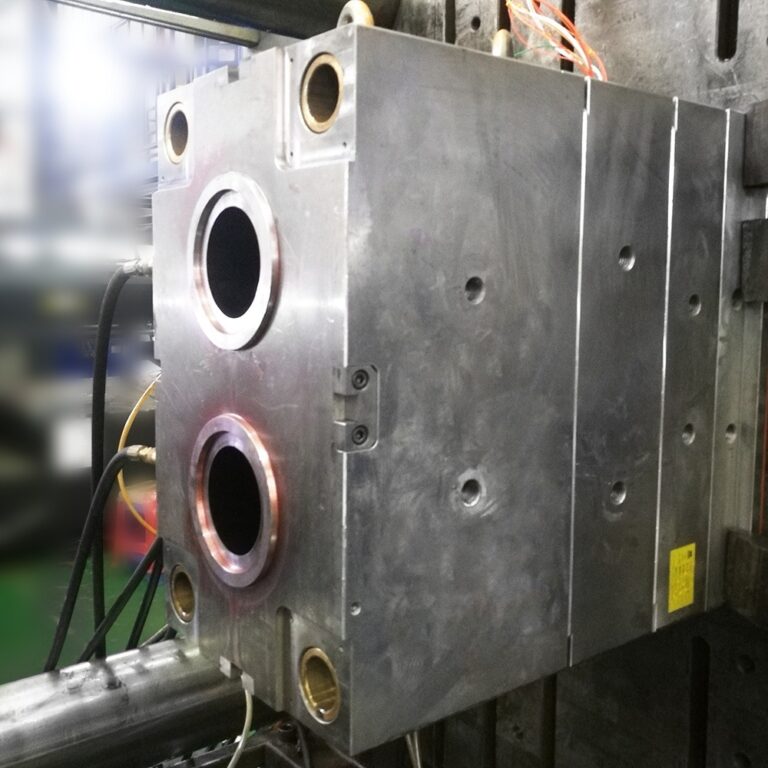

(2) ensure the smooth surface of the injection mold

If in the injection molding process, the mold surface is not smooth enough, it will affect the surface finish of plastic products, but also easy to cause plastic products sticky mold situation, so it is difficult to ensure the integrity of the product, so in order to avoid this situation, in the injection mold processing and manufacturing as smooth as possible when the mold surface processing some.

3) The design of the exhaust hole must not be forgotten

Why do we need to design the air venting hole in the injection mold? Because if the mold sealing is done very well in the injection molding process, it is likely to lead to a large number of air bubbles inside the melt after injection, which will also affect the quality of the product, so in order to avoid this situation, then in the injection molding process must be designed to vent the air inside the mold and some bubbles in the melt. The air inside the mold and the air bubbles in the melt can be drained out.