The service life of the mold is the total number of productions that can be processed by the mold under the premise of ensuring the quality of the product parts processed, it includes the life of the working surface after several times of resharpening and replacement of wearable parts. Here a look at what factors will affect the life of the plastic mold?

What factors will affect the life of the plastic mold?

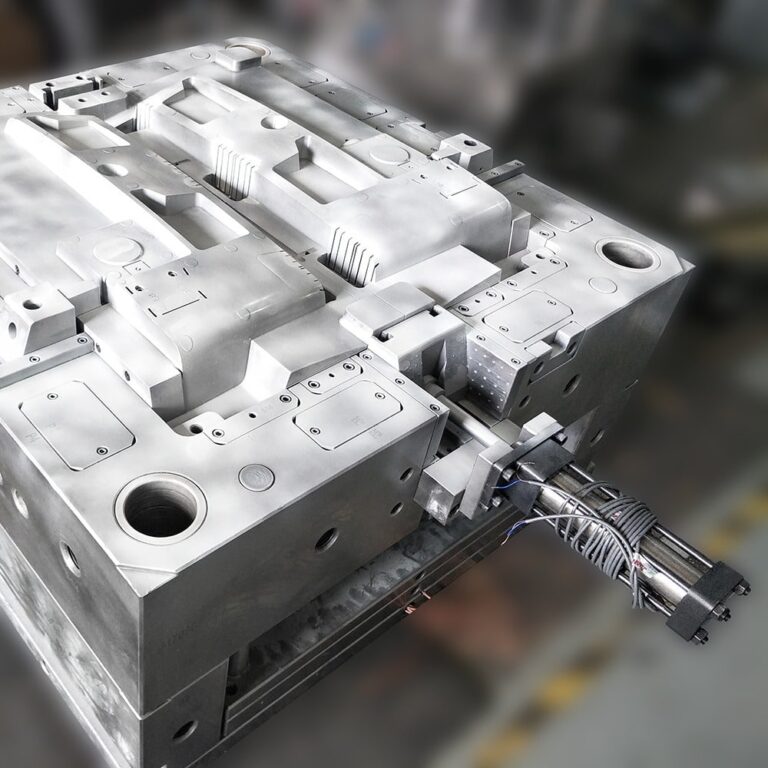

1, Mold structure

Reasonable mold structure helps to improve the bearing capacity of the mold and reduce the thermal and mechanical load on the mold. Reliable mold guide mechanism can avoid mutual gnawing between the convex and concave mold; cold pier and cold extrusion mold bearing high strength load can prevent stress concentration through the cross-sectional size change processing.

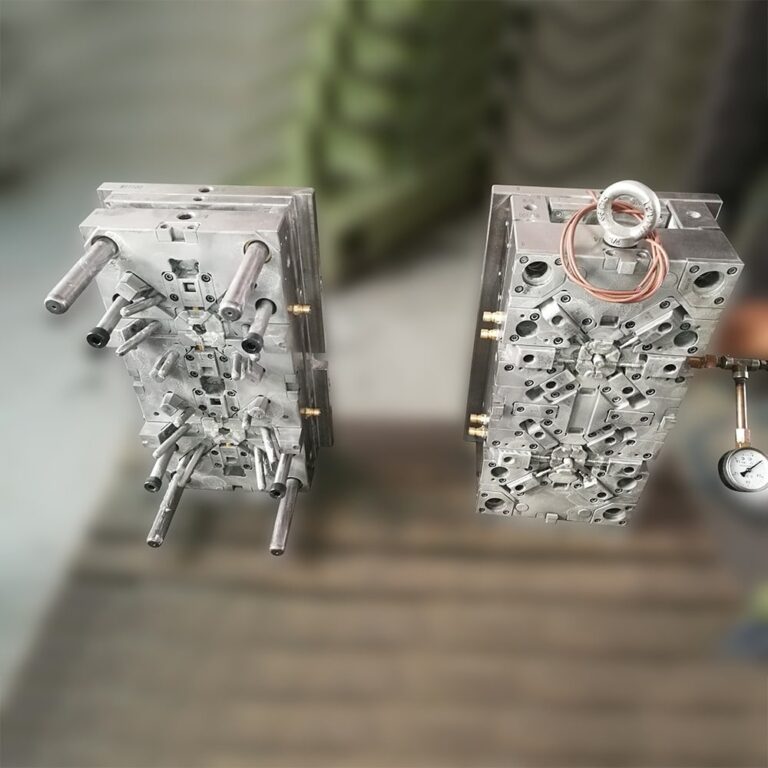

2,Mold material

Mold life and its material has a great relationship, the greater the number of production, the greater the working time of the load on the material requirements are also higher, for this, should be selected with strong load-bearing capacity, long service life of high-performance mold materials.

3, Mold processing quality

Mold parts in the processing, heat treatment process defects will affect the mold life. Such as: the mold surface residual knife marks, EDM microscopic cracks, heat treatment of the surface layer of carbon powder and decarburization and other defects have an impact on the bearing capacity and life of the mold.

4,Mold working condition

When the injection mold is working, it should frequently go through the process of mold closing, locking, injection, pressure-holding, cooling, mold opening, ejecting, etc. In this working process, it is necessary to ensure that each working mechanism works reliably and flexibly, for this reason, it is necessary to make the moving parts move without obstruction and have reliable lubrication, which requires the operator to pay attention to the maintenance and repair of the mold, so that it is in good working condition.

5,The condition of product parts

The surface quality state of the processed parts material, material hardness, elongation and other mechanical properties, the dimensional accuracy of the processed parts, etc. have a direct relationship with the mold life. Such as: nickel quality fraction of 80% of the special synthetic shape is very easy and mold work surface occurs strong occlusion phenomenon, so that the work surface occlusion hair pulling, directly affect the mold can work properly.