Factors affecting the precision of parts produced by injection mold:

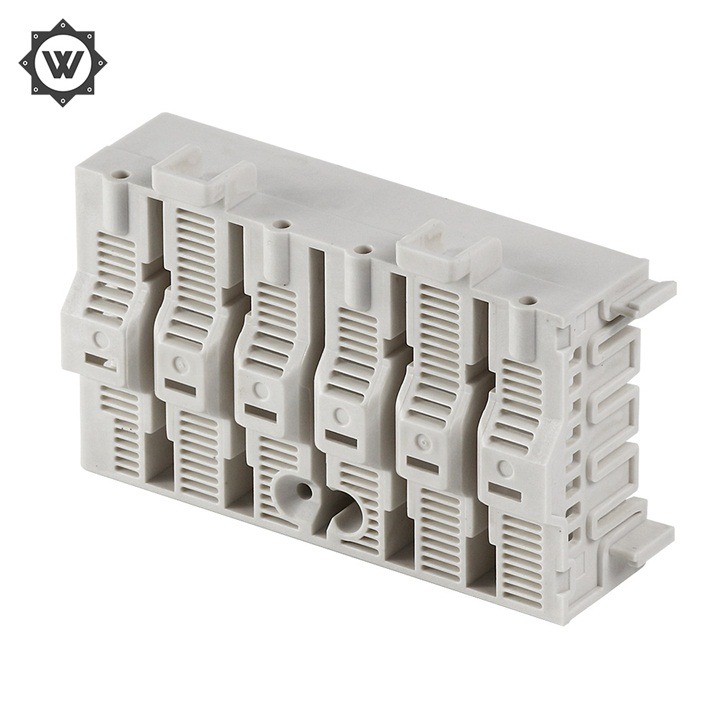

1) Molding materials: plastic shrinkage, fluidity, moisture, volatile content, raw material allocation process, production batch, etc. can affect the precision of plastic parts produced by injection mold.

2) Process conditions: molding temperature, pressure, time, shrinkage.;

3) Part shape: shape, wall thickness, molding shrinkage, demoulding slope, etc;

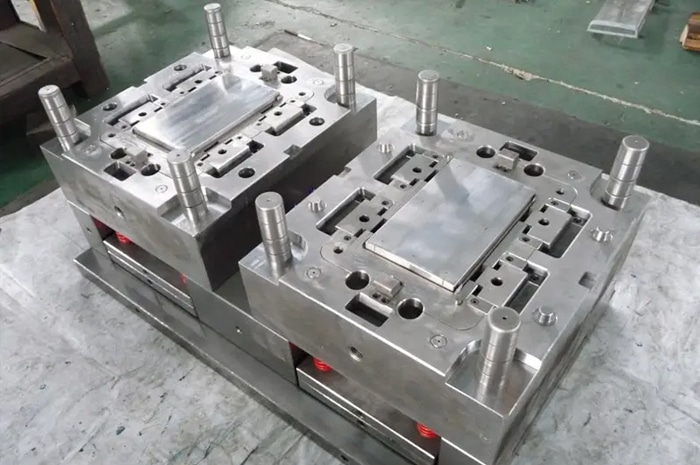

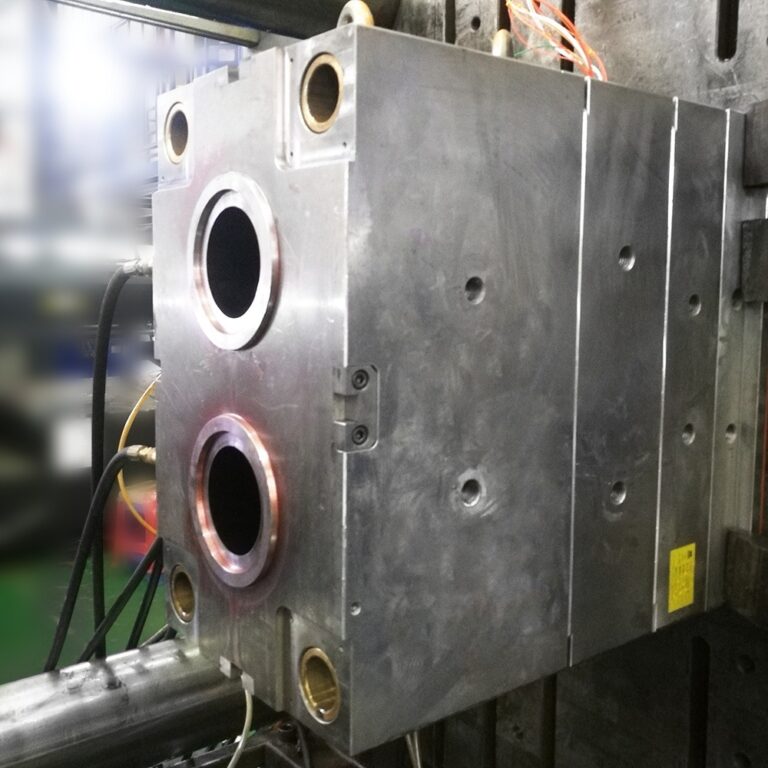

4) Injection mold: manufacturing precision, wear degree, shape and structure, shrinkage direction;

5) Aging change after forming: post shrinkage, improper storage will lead to bending, twisting and other deformation.

It can be seen from the above analysis that the dimensional accuracy of plastic parts is often not high, so a lower accuracy level should be selected on the premise of ensuring the use requirements.

(3) Tolerance:

Tolerance selection is one of the important factors affecting the precision of parts produced by injection mold:

1) The precision of fit dimension is higher than that of non fit dimension;

2) Due to the influence of shrinkage fluctuation, small size is easy to reach high precision;

3) Different plastics have different shrinkage and dimensional stability;