What is a precision injection mold?

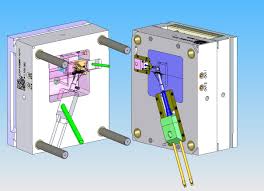

A precision injection mold is a device to obtain a product of a certain shape after injecting resin material into a metal model. In fact, in order to control the temperature of the mold, there are cooling holes, heaters and other devices on the mold that allow the refrigerant to pass through. The material that has become molten enters the main flow channel and enters the mold cavity through the diversion channel and the pouring port. After the cooling stage, the mold is opened and the top device on the molding machine takes the top rod and pushes out the product. The molded product consists of the mainstream channels that lead the molten resin into the mold cavity and the product.

Precision injection molds are used to mass produce some complex shaped parts or products by precision machining methods. Specifically, various molded products are obtained by heating molten material that is injected into the mold cavity under high pressure and after cooling and curing.

Precision plastic molds mainly consist of a concave die assembly substrate, a concave die assembly and a concave die assembly. A concave mold with clamps forming variable cavities is a convex mold with variable cores formed by a convex mold combination substrate, a convex mold assembly, a convex mold combination clamp, a cavity cutting assembly, and a side cutting combination plate. Abrasive convex, cavity and auxiliary forming system software are fused to transform. It is possible to produce and process plastic parts of series products with different looks and specifications.

Resin enters the mold cavity, and we usually design the length of the diversion channel to be the same length. The main flow channel and the diversion channel in the molded product are not products and are sometimes discarded or crushed as molding materials. We call this recycled material. Recycled materials are generally not used as molding materials alone, but are usually mixed with new materials. This is because the mechanical properties, flowability, color and other characteristics of the resin change after a single molding.

*** Translated with www.DeepL.com/Translator (free version) ***