What Is The Main Flow Of Plastic Mold?

The main runner refers to the section from the contact part of the injector nozzle and the mold to the branch runner.

Design considerations:

(1) The end face of the sprue is usually circular.

(2) In order to facilitate demoulding, the main runner is generally made with a slope. However, if the main runner passes through multiple plates at the same time, pay attention to the slope and size of the holes on each block.

(3) The size of the main runner shall be designed according to the flow characteristics of plastic materials

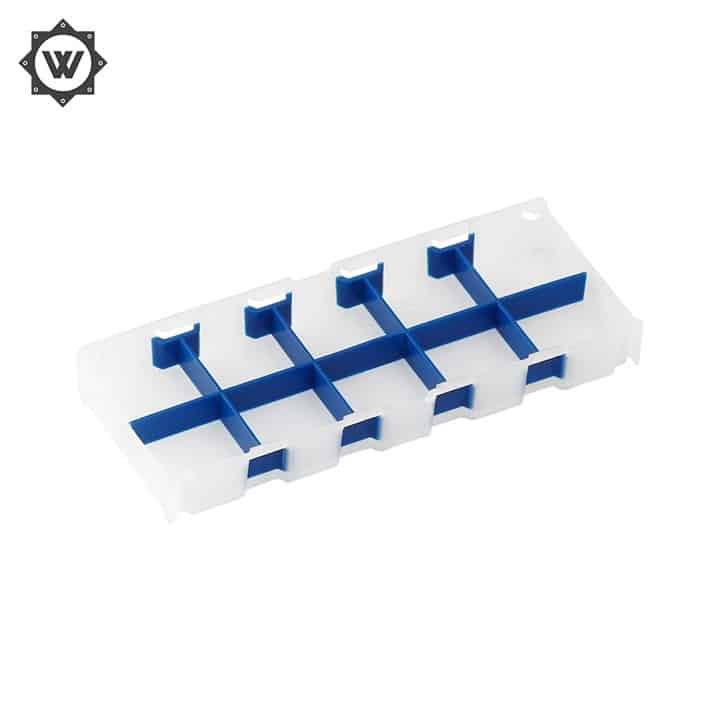

(4) The main runner is mostly conical in design (As shown in the figure) Pay attention to:

A. Small end diameter D2=D1+(0.5~1mm)

B. Radius of small end ball R2=R1+(1~2mm)

(D1 and R1 are respectively the diameter of the injection outlet of the injection machine and the spherical radius of the injection head)

spruebush

As the main runner contacts and collides with the high-temperature plastic and nozzle, the main runner part of the mold is usually designed as a removable and replaceable bushing, referred to as the pouring sleeve or gate sleeve

(1) Its functions mainly include:

A. It is convenient for the mold to enter the positioning hole during installation, and it is well positioned on the injection molding machine to fit with the nozzle hole of the injection molding machine, and can withstand the back pressure of the plastic, so as not to be pushed out of the mold

B. As the main channel of the gating system, the plastic in the barrel is transferred to the mold to ensure that the material flow can reach the mold cavity effectively and smoothly. There should be no plastic overflow during the injection process, and the condensate in the main channel can be easily removed.

(2) The structural forms include integral type and split type

Integral type: the shoulder is integrated with the main channel

Split type: that is, the shoulder is made separately from the main runner

Japan’s industrial standard: JIS

China’s industrial standard: SJB