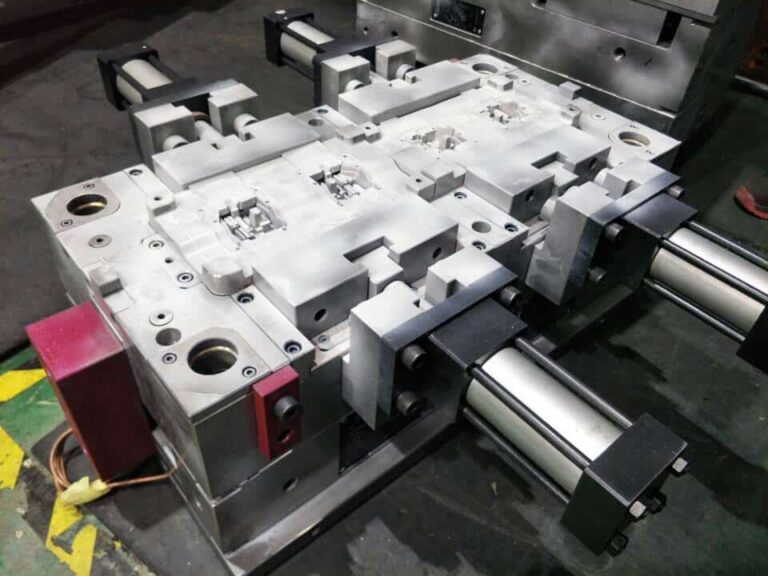

The maintenance and repair of automobile dies usually refers to the maintenance of mass production dies by automobile factories, including daily spot check, cleaning, repair, maintenance, etc. of the dies. The purpose is to ensure that the dies are in a state of complete functions, normal operation, and qualified stamping products, and ensure the normal progress of daily production activities.

Classification of mold maintenance items:

The mold maintenance items are classified into general maintenance items and key maintenance items according to the difficulty of maintenance work and the degree of impact on production.

The general maintenance and servicing items include the maintenance and cleaning of the mold, the general spot check of the mold, and the handling of the problems in the general spot check items, which are basic work, specifically including:

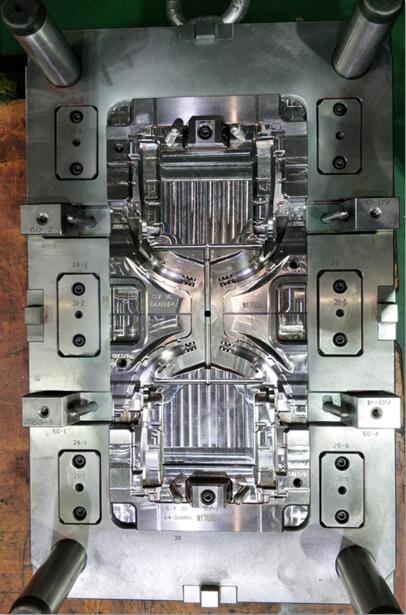

⑴ Maintenance and cleaning of the mould: the mould shall be cleaned regularly to remove burrs, oil stains and other garbage, old, dirty and deteriorated friction pair lubricant, and replaced with new lubricant.

(2) General spot inspection of the mold: it refers to the regular spot inspection of the mold structure and various functional parts of the mold, to confirm whether each part is in a state of complete structure, normal function and normal production, and to preliminarily confirm the parts suspected of cracking.

(3) Treatment of problems in general spot inspection items: it refers to the repair and treatment of simple problems found in general spot inspection, including simple repair of die drawbead, local small range of pressing surface, repair of knife edge breakage, simple polishing repair of flanging surface, replacement of simple standard parts (including but not limited to punch, round die, polyurethane, etc.), etc.

Key maintenance and repair items refer to the repair of maintenance items with great technical difficulty, impact, risk, long repair cycle, and relatively professional technical requirements, including the inspection and maintenance of mold chromium layer (if the mold has chromium plating), inspection, tracking and treatment of mold cracks, management of mold welding, inspection and maintenance of nitrogen spring, etc.

General maintenance and maintenance management of moulds

General maintenance includes three aspects: maintenance and cleaning of molds, general spot check of molds, and handling of problems in general spot check