What will affect the lead time of plastic mold processing companies?

As we all know, the processing cycle of plastic mold is relatively long, and its processing steps are many, and the process is complex. Therefore, it is inevitable to encounter many factors that are difficult to effectively control in the entire processing, among which the delivery date is a problem that most customers care about. Sometimes, even though the manufacturer’s production equipment and process level are almost the same, the delivery date is still different. Why does this happen? What are the factors that affect the delivery date of plastic mold processing companies?

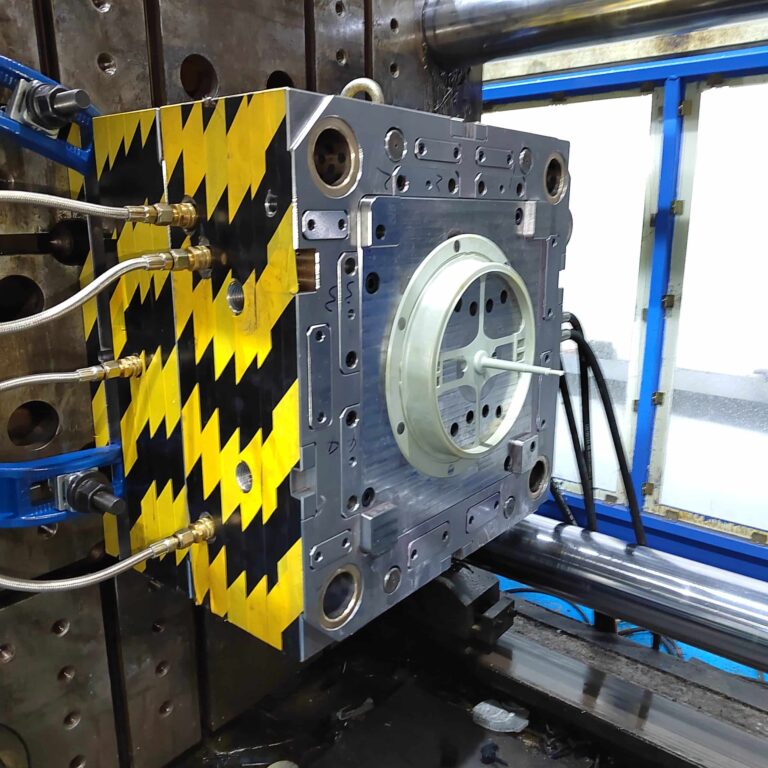

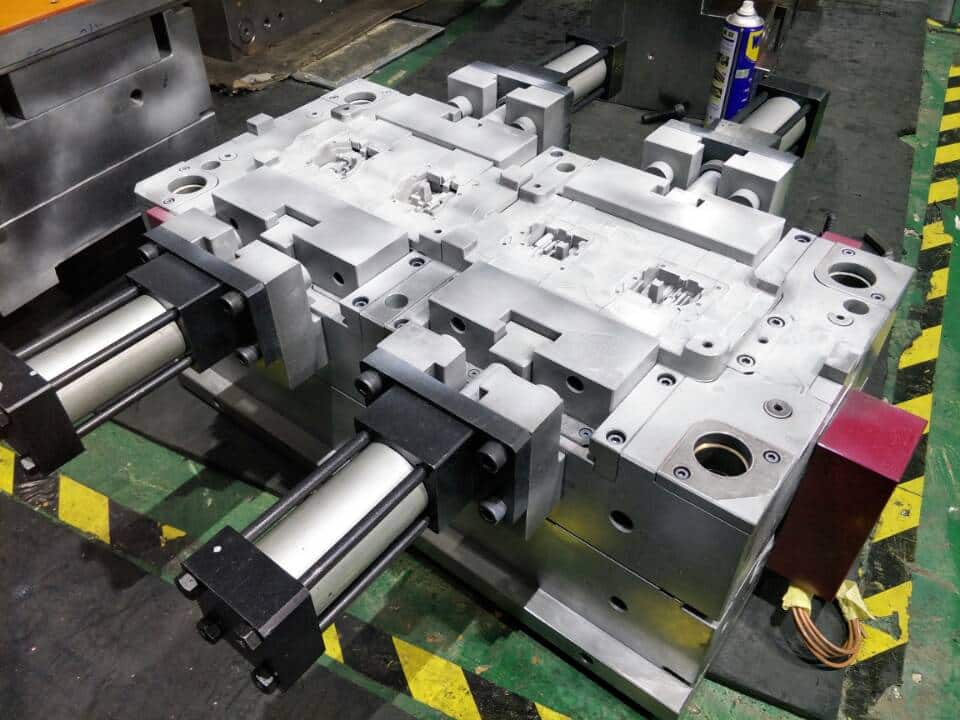

1. The larger and more complex the design size of plastic parts, the longer the processing time of natural plastic mold and parts will be.

2. In addition, the material performance of the product has different requirements on the steel of the mold and the processing technology of the mold, and the time will also be different.

3. According to customer requirements, the appearance requirements and dimensional accuracy of injection molding products are also important factors that affect the processing cycle of plastic molds.

4. How much is the expected output of the injection mold? Is the mold making multiple holes or one hole. There must be a difference between two products and one product, and the processing time will be longer.

5. The more complex the shape of plastic parts, the more difficult it is to process plastic molds. That is to say, the more classified plastic parts are, the more assembly positions, buckle positions, and hole positions are. The more difficult the mold processing is, the longer the mold processing time is.