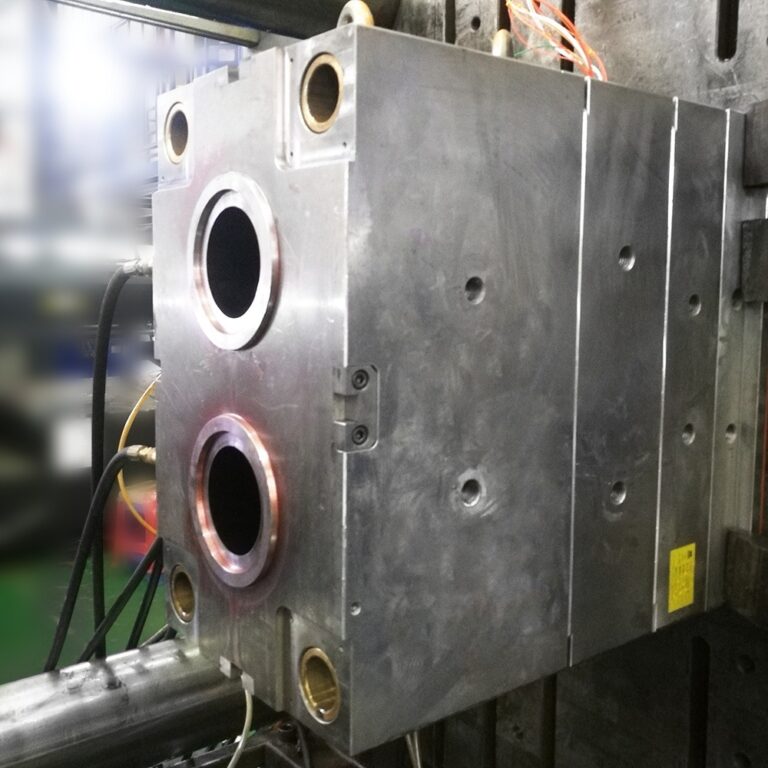

Die failure is the most common problem in stamping production, which often causes production stoppage and affects the production cycle. Therefore, it is necessary to find out the cause of mold failure as soon as possible and maintain it reasonably.

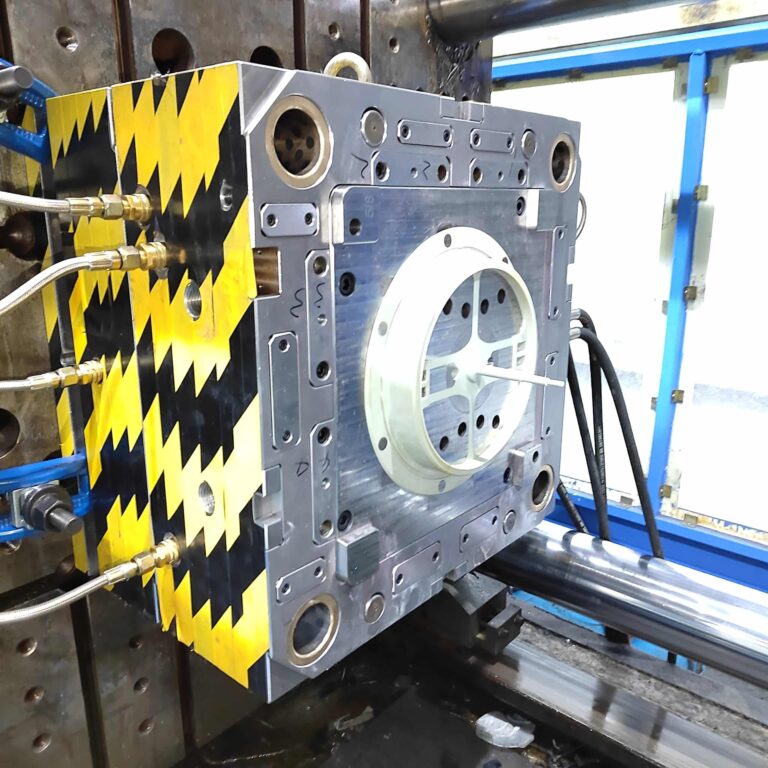

First of all, we need to take into account the high mold costs of injection molding production. Usually, mold costs account for about a quarter of the total cost of parts. This is mainly because mold manufacturing is difficult and the cost is high. The mold repair and maintenance costs after the weapons are put into production can not be underestimated, and the mold cost may only account for about 40% of the entire mold cost. Therefore, if the mold can be repaired in time, It can greatly reduce the mold cost of injection molding production to a certain extent.

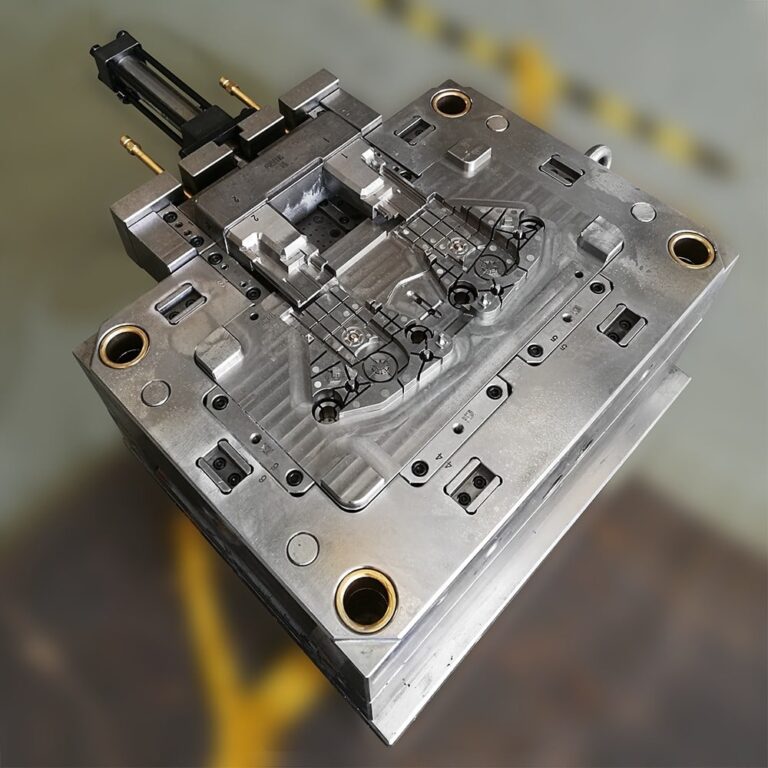

After the mold is damaged, it is faced with the problem of maintenance or scrapping. The plastic mold fails due to unnatural wear, such as the damage of non key parts. And the damage of small parts. Most of them can be completely restored to the producible state through maintenance, and then put into injection molding production again. However, when the key parts of the mold are seriously damaged, the front mold and the rear mold are damaged at the same time. The one-time repair cost exceeds 70% of the original cost of the mold or the life of the mold is near. Then such maintenance is of little significance. It should be considered to scrap this set of molds.

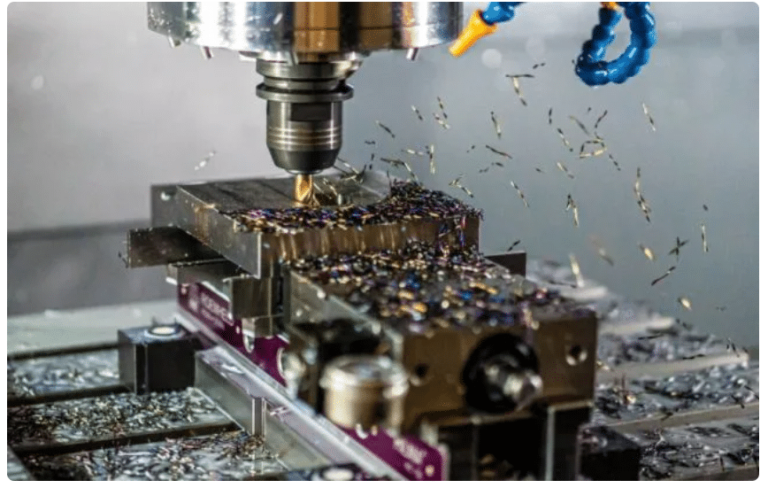

In addition to large molds and molds with complex structures. When the mold repair technology is too complex, the mold repair cost is too high, and the difficulty will inevitably lead to a long maintenance cycle, which seriously affects the normal production of injection molding, at this time, it is necessary to improve the selection of invalid scrap and re manufacture the mold.

Injection molding production efficiency and cost depend heavily on the mold. In case of any failure of the die in the production process, the specific problem shall be analyzed and the correct maintenance plan shall be formulated. Timely solve problems such as mold damage, clamping and product quality defects. Only by properly handling the relationship between mold maintenance and scrap can we reduce the downtime for maintenance, shorten the production cycle and ensure the normal operation of injection molding production.