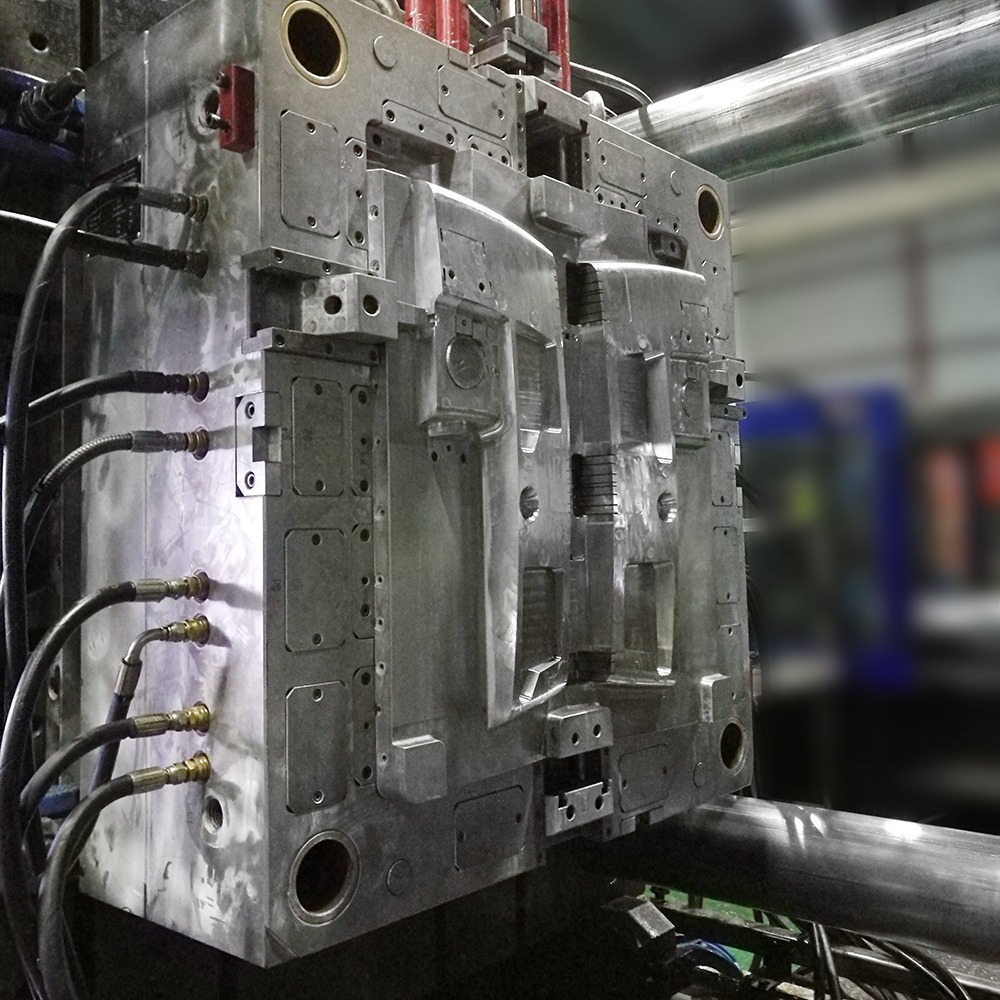

Why should the injection mold be tested after processing

After the injection mold is processed, the mold test is the last step to check whether the mold can produce qualified products. It can be said that mold trial is a comprehensive inspection of our mold development and design, and the results of mold trial will directly affect the production and quality of the factory products.

Why should we try the mold?

Mold is a precision instrument, and some problems in the production process are not found with the naked eye. In addition, precision tools need to be modified many times to be qualified. Some minor problems must be found and solved before production. In the process of manufacturing, it is very likely that storage and processing will not be available, so it is necessary to test the mold, and then analyze, evaluate and optimize the samples produced by the test mold to meet the requirements of high quality. However, the defects of most molded products are caused in the plasticizing and injection molding stages, and may also be caused by improper manufacturing of plastic molds. Therefore, in order to avoid product defects caused by mold design, it is necessary to analyze mold design and process parameters when making molds.

What are the advantages of injection mold trial?

Although the process parameters and mold design of the injection mold can be optimized, the production cost of the injection mold will also be increased. If the injection mold structure is found unreasonable after the mold test, the injection mold needs to be improved, which will undoubtedly make the injection cost exceed the budget. For example, some injection molds are well designed, but the process is not in place. When the best molding process and injection model are not selected for the trial mold, it is obvious that the mold is well done, but the products after injection molding are not good. Also, it often happens that the physical properties of plastics are not fully understood and the shrinkage is not accurate. What makes people vomit blood is that many situations are not satisfactory, and even the injection mold has to be scrapped and redone.

Make the best preparation for mold test.

1. Understand injection molding products

The engineer needs to know the shape and structure of the product in advance, the structure that is easy to cause problems and the characteristics of the product, so as to quickly find out and timely adjust and solve the problems during mold testing.

2. Prepare drawings

Before T1, it is necessary to prepare the mold test drawing. If there is no drawing provided by the customer, the manufacturer needs to mark the length and width of the product according to the mold opening 3D to facilitate the caliper measurement. At least two dimensions are required to facilitate timely adjustment during mold test.

3. Prepare measuring tools

According to the size of the drawing, prepare appropriate measuring tools, or inspection tools, and adapt the samples to facilitate measurement, detection and verification.

4. Familiar with raw material properties and processing conditions

The project needs to be familiar with the physical property table of the raw material, and be able to judge whether the molding conditions are in a reasonable range on the spot.

5. Issue the notice of mold test

According to the product weight, mold characteristics, size and regular requirements, the project issues a mold test sheet to facilitate the production management to arrange a suitable machine. The mold test sheet needs to indicate the water connection method and requirements, and the mold test is preferred according to Mold Flow conditions.

6. Determine equipment

It is also necessary to confirm whether the auxiliary equipment for mold testing, such as the number of water pipes required for the mold, the number and performance of water source interfaces and other infrastructure hardware facilities can meet the requirements for mold testing, and also need to prepare thermometers.

7. Notify relevant participants

The quality personnel shall be informed to participate in the mold trial, and the mold project, product project, fitter and designer shall be informed to participate in the important mold. If the mold problem reaches the technical bottleneck of the company, each department shall discuss the scheme on the site.